Waterjet Cutting

Versatility, Power, Cost Effective

The Advantages of Waterjet Cutting

Waterjets are CNC driven cutting tools that use a stream of high-pressure water, mixed with an abrasive, to cut through virtually any material. Developments in Industrial Waterjet technology over the years have allowed for the process to become more cost effective and efficient for a multitude of applications. Many fabricators and machinists prefer Waterjet-cut parts over laser and plasma cut parts due to its superior dimensional tolerances, and no mechanical-stress added during the cutting process due to heat. IRC Aluminum & Stainless operates some of the largest Waterjet cutting tables in the Pacific Northwest. Our vast operational knowledge and experience allows IRC to create and customize Waterjet applications to our customer's exact needs.

IRC's Flow Mach 700 Waterjet

4" Thick Stainless Steel Plates

IRC’s Waterjet Cutting Capabilities

IRC has multiple Flow and Omax Waterjet cutting systems. All of our Waterjets are custom fabricated and outfitted to serve IRC’s fundamental cutting requirements. Since IRC Aluminum & Stainless’s core cutting competencies consist of production cutting and custom cutting projects, our Water Jets are larger in size compared to machines installed at other Waterjet cutting companies. With our largest cutting-table sizes being up to 13'ft x 28'ft, and our smallest cutting machines being 10’ft x 28’ft. One of our Flow Waterjets has over 24"inches of Z-axis clearance / travel distance (for cutting on pre-fabricated weldments and thicker materials). All of IRC’s Waterjets have multiple fixed cutting heads for long production runs and reliability. Finally, IRC is also a mill-direct distributor or stainless steel and aluminum plate products: making us a one-stop-shop for materials and cutting services and adding stream-lined value to our customers.

13’ft x 28’ft Cutting Envelope

Cutting Hard Metals Up to 13"inches Thick

Metals, Plastics, Rubbers, Castings, Composites

High Tolerance Parts Up to +/-.005"

Etching and Part-Marking

Cutting Small Holes in Thicker Metals

Large Parts and Small Parts

Production Cutting

Superior Edge Quality

Cut Quality Levels

IRC Aluminum & Stainless offers three different levels of Waterjet cut-quality (A, B, and C). Each level varies in edge roughness, tolerance, and taper. The differences between IRC’s cut quality levels are based on feed-rate and price. Selection is based on material thickness and the application (see cut-quality images below: 2" thick 316 Stainless).

Waterjet A-CUT

(+/-.005", Edge Taper: .010" per side)

Waterjet B-CUT

(+/-.015", Edge Taper: .030" per side)

Waterjet C-CUT

(+/-.030", Edge Taper: .060" per side)

Common Parts & Shapes

Plates & Panels

Plate Flanges

Machining Blanks

Near Net Shapes

Fabrication Parts

Signage Text & Logos

Architectural Elements

Gears & Sprockets

OMAX Waterjet Cutting Large Parts

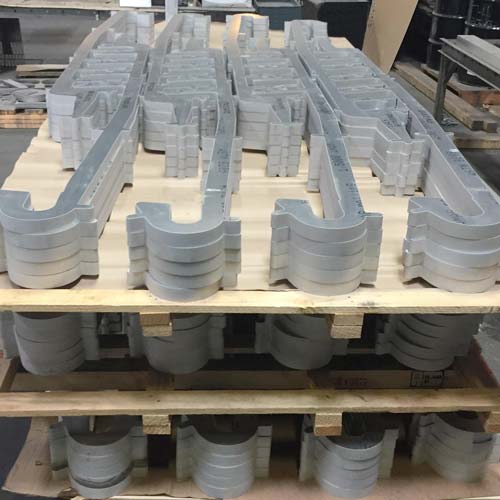

IRC Waterjet-Cut Blanks

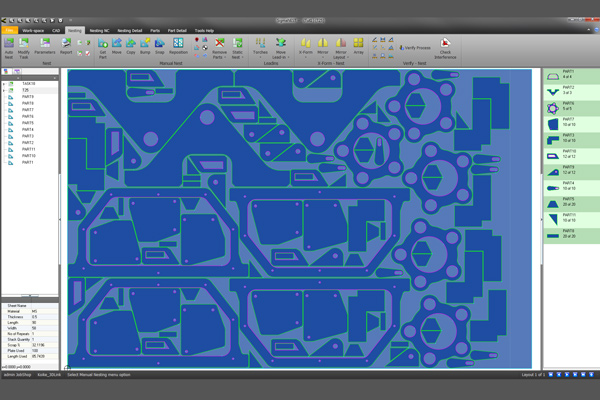

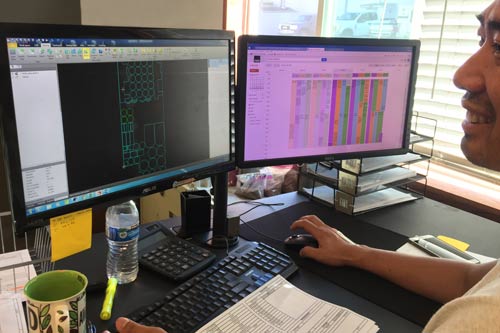

CAD & Nesting Capabilities

IRC's programmers are well versed in two dimensional CAD and layout-nesting. Our ability to nest your parts in order to attain the highest material yield is second to none. We utilize Sigmanest® nesting software for programming and layouts. IRC is committed to providing the best and newest technology to ensure efficient manufacturing methods and accuracy for parts.

IRC accepts .dxf or .dwg file types, 2D drawings only.

IRC Part Nesting

IRC Waterjet CAD

Outside Processing

IRC offers sourcing for metal-working processes that we do not perform in-house. Utilizing IRC’s extensive vendor network, we are able to offer services such as: Machining (milling and turning), Bending / Forming, Rolling, Surface Grinding (Blanchard grinding), Metal Polishing, Welding, Heat-Treating, and more. Just ask one of our sales reps.

Machined and Beveled Stainless

Rolled Stainless Steel

Forming / Bending Parts

How to Order From IRC

Getting a quote or placing an order with IRC is simple. Just follow these five easy steps for submitting your part drawings, dimensions, or shapes to one of our inside sales representatives. Our inside sales representatives will send you an email with a quote, momentarily. If the parts are just rectangles, squares, or circles; then just providing the required dimensions will be sufficient for pricing. You are welcome to email IRC directly or submit your drawings and requests or by using our online “Request A Quote” form. Or give us a call!

(Drawing Files) .dxf or .dwg file types, 2D drawings only

(Material Type) Metal, Plastic, Rubber, or Other

(Material Origin) Purchase materials from IRC, or customer provided materials

(Thickness) Thickness of material

(Quantities) Part quantities